()

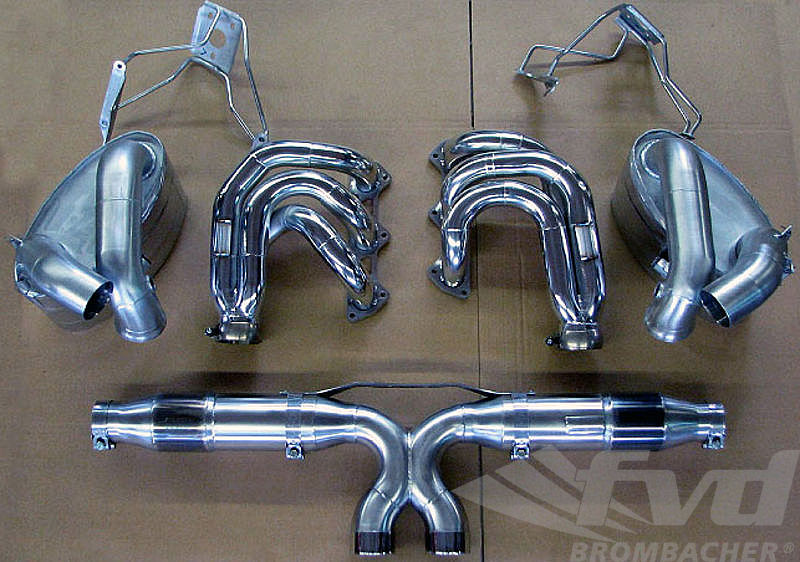

Exhaust System 997.1 GT3 "Brombacher" (Sound Version), Stainless, 200 Cell Cats, Dual Tips

Reference No.: BES 997 102 60S

Expected in 4-14 days

$ 7,772.00

without Shipping

without Shipping

Description

- + 25 crank hp & + 27 crank torque- 200 Cell high flow, tri metal german HJS sport catalysts. Cats are located behind the muffler for even greater Hp & torque.

- Equal length header set up with merge collector for maximum torque gain

- 2 3/4" tubing (70mm) straight through design for max. power

- Weighs 64.3 lbs. (29,2 Kg)

- German V2A - X5CrNi18-10 - 1.4301 stainless steel for improved durability

- 2 x 3"(90mm) round tips

- Cone style catalytic connection design to prevent exhaust leaks

- Includes quick release clamps

- Made in Germany

- Approximately 110 dB

- Intoxicating growl at idle, partial throttle and wide open throttle

- No DME programming necessary.

Weight Savings:

997 GT3 OEM Exhaust Weight:

Stock primary muffler 22lbs each (44lbs total)

Stock secondary muffler and tips 20lbs

Stock headers and cats 11.25lbs each (22.5lbs total)

Stock exhaust system 86.5lbs total

FVD 997 GT3 Sound Version Exhaust System:

Header, Cats, Muffler and hardware = 64.3 lbs

= 22.2 lbs lighter than stock exhaust!

The FVD GT3 sound version exhaust gives the 997 GT3 a more pronounced, aggressive sound similar to the 997 Cup Car. Our design includes the catalytics behind the muffler's for substantial power gains. Our exhaust is much less restrictive than the factory system and provides additional weight savings in the rear of the vehicle. Our exhaust system offers impressive gains in performance, especially in the mid range, and produces an incredible sound that is pure Porsche!

Installation made easy! Replace worn hardware and gaskets with one of our prepackaged installation kits.

Use Part # FVD MK9 972 02

FVD is proud to introduce our newest line of Brombacher exhaust systems. Brombacher exhausts are engineered for the discerning Porsche owner and offer unmatched performance, unparalleled quality, and incredible value. All of our exhausts are manufactured in Germany and are tested comprehensively for flow rate characteristics, thermal stress, resistance to cracking, and longevity.

Brombacher mufflers outer shell dampens and eliminates unwanted frequencies and ensures no resonance or drone in the cabin. The end result is a strong, linear, firing-order dominated flat-6 Porsche sound. In addition, Brombacher exhausts systems are available for ultimate performance full titanium. Our titanium system's are nearly 40% lighter compared to steel and are available for late model, water cooled applications. Each of our exhaust's have been extensively tested on both a chassis and engine dyno as well as logged thousands of miles on both the street and at the track. All this research, development and testing ensures maximum horsepower gains throughout a broad power band; all while maintaining reasonable sound levels for the street and provide a distinct, sporty exhaust note that is purely Porsche.

Like all European Vehicles, FVD parts are TÜV approved. What is TÜV approval you ask? Basically, German-registered road vehicles may not be operated on public roads without a certificate from the TÜV. Also, all modifications must be approved, from installing tires of a different size to materials used in nuts and bolts. TÜV's safety guidelines are among the strictest in the world, and getting a road permit for thoroughly customized vehicles borders on the impossible.

We strongly suggest replacing worn gaskets and hardware with our pre-packaged installation kits.

FVD's parts passed these criteria in order to obtain the TÜV stamp of approval:

- Corrosion Test – Exterior metal parts (ie exhaust, brakes, rims, etc.) must undergo a HCL (Hydrocloric Acid) bath, which speeds up the corrosion process. This ensures long lasting, highly durable parts which benefit the end consumer.

- Extreme Temperature Test – Items are put through –40 degree's Celcius to + 85 degree's Celcius sudden temperature change. This test ensures that material expansion and contraction does not cause cracking or material inconsistency.

- Material Analysis – Chemical and Microscopic material analysis is done to determine the correct percentages of Iron, Zinc and many other elements. This also ensures material consistencey and longevity.

- Exhaust Temperature Test – Exhaust items are also put through a series of extremely high temperature tests in order to assure the consumer that parts can withstand cracking and splitting. Test temperatures exceed 1,400 degree's Celcius!! For reference normal exhaust gas temperatures are only 800 degree's Celcius.

FVD Exhaust Systems Carry A 2 Year Warranty!